A formative human factors study plays a pivotal role in the design process, particularly in industries where usability directly impacts safety, efficiency, and regulatory compliance. This research method, typically conducted during the early to mid-stages of the design process, provides actionable insights to align the product with real-world user needs and workflows. Beyond improving usability, formative studies deliver significant business value by reducing costly redesigns and enhancing a product's competitive edge.

When to Conduct a Formative Human Factors Study

Formative studies are most effective during the early stages of the design process, when prototypes or workflows remain flexible. By iterating on the design based on user feedback, teams can identify and resolve usability issues before they escalate into expensive fixes later in development. Repeating formative studies at key points throughout the design process ensures that the product evolves in step with user expectations and emerging requirements.

Why Conduct a Formative Study?

The primary goal of formative studies is to proactively identify potential user challenges, especially those that could lead to errors, frustration, or inefficiency. In high-stakes industries like healthcare, addressing these challenges early helps mitigate risks, enhance safety, and ensure compliance with standards such as the FDA’s human factors guidance for medical devices.

From a business perspective, formative studies create products that resonate more effectively with users, driving customer satisfaction and market adoption. They also streamline regulatory approval by ensuring the product design adheres to usability and safety standards, reducing delays and associated costs.

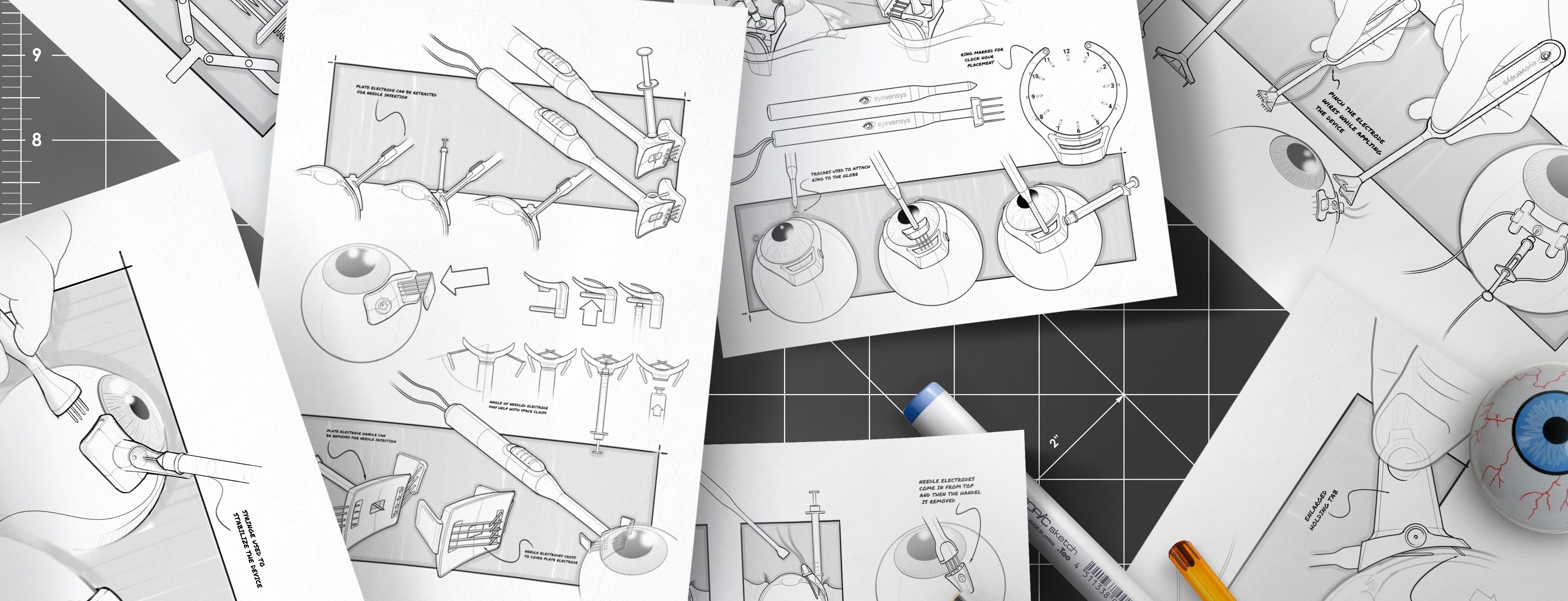

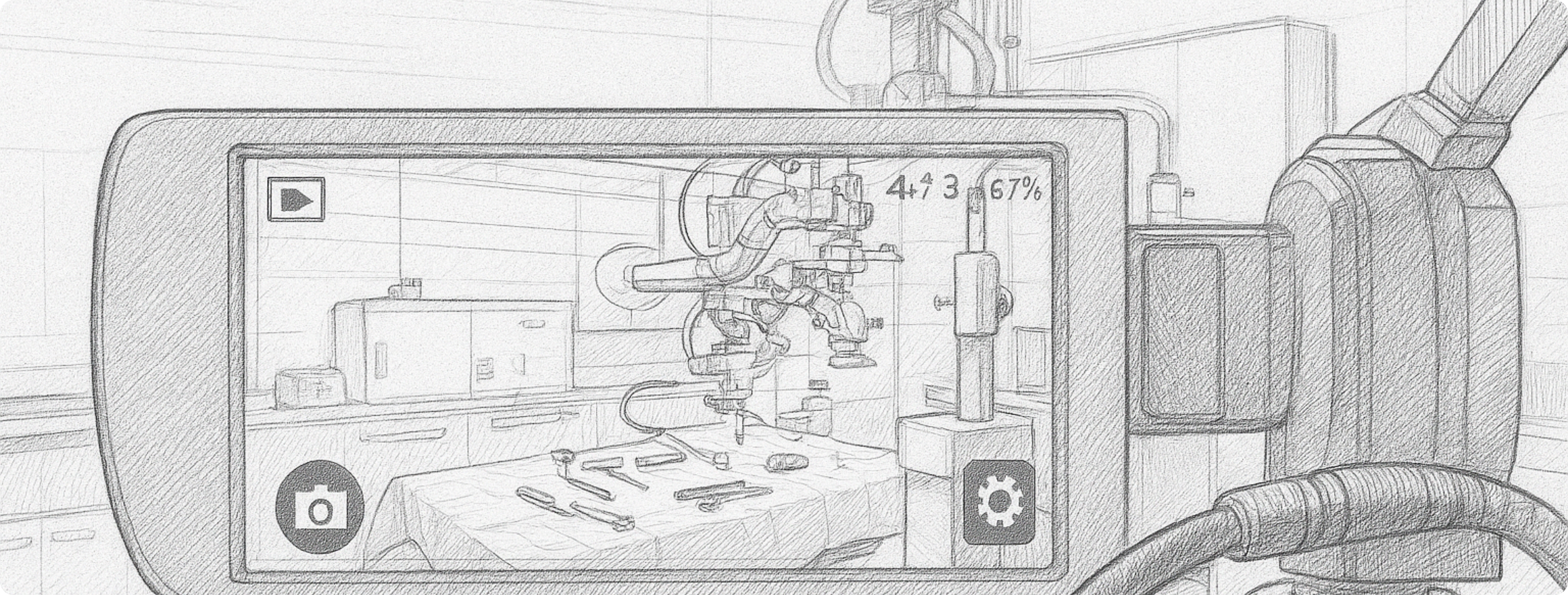

Ethnographic Methods in Formative Studies

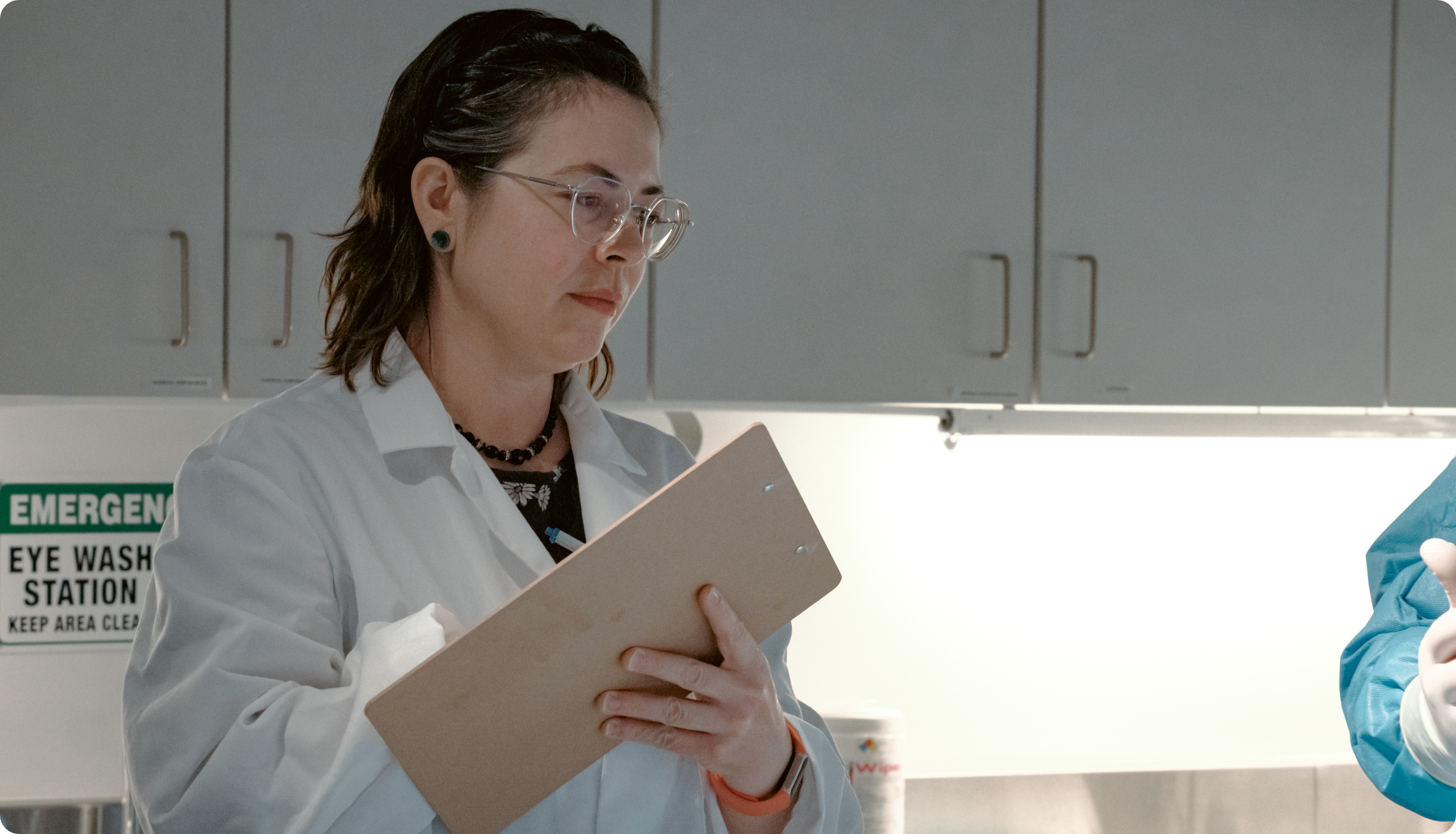

Ethnographic research is a cornerstone of formative human factors studies, offering deep insights into how users interact with products in real-world settings. Methods such as observational studies, contextual inquiries, and think-aloud protocols help uncover hidden pain points and inefficiencies that might not emerge in controlled environments. For example, observing medical professionals using a device in a clinical setting can reveal critical workflow issues that may be overlooked in a simulated lab.

These methods allow designers and engineers to empathize with users, enabling them to create products that better accommodate user environments, limitations, and preferences. This user-centered approach enhances product usability and builds a reputation for intuitive, high-quality solutions—key drivers of customer loyalty.

FDA Guidance and Compliance

In regulated industries, following FDA human factors guidelines is essential. The FDA emphasizes that human factors studies, including formative testing, must demonstrate that users can safely and effectively operate the product under real-world conditions. Formative studies aligned with these guidelines provide evidence of due diligence and risk mitigation, paving the way for smoother regulatory submissions.

The Business Value of Formative Studies

Beyond usability and safety improvements, formative studies deliver significant business benefits. By identifying usability issues early in the design process, these studies help minimize development costs and prevent expensive late-stage redesigns. Products created with a strong focus on user needs are more likely to succeed in the marketplace, driving customer satisfaction and loyalty. Additionally, addressing regulatory requirements early reduces the risk of delays or setbacks in bringing products to market.

Conclusion

Formative human factors studies are more than a tool for improving usability—they are a strategic investment in product success. By integrating ethnographic methods and adhering to FDA guidelines, these studies enhance safety, usability, and user satisfaction while providing measurable business advantages. Incorporating formative studies at the right points in the design process enables companies to create products that are safer, more effective, and better aligned with user needs, all while optimizing costs and time to market.

For over 7 years, Kaleidoscope Innovation has been a trusted partner for industry leaders like Eli Lilly, Pfizer, and Baxter to bring safer, smarter medical products to life. Our integrated Human Factors expertise ensures that usability is built in, helping you reduce risk, accelerate development, and deliver intuitive, high-performing solutions. Whether you're launching a new product or refining an existing one, we’re here to support every step of the process. Let’s talk about how we can help elevate your design through formative research.

Back to Insights + News