The orthopedic segment is currently undergoing a remarkable transformation that is fueled by the convergence of smart implants and artificial intelligence (AI), ushering in a new era of innovation. This powerful combination is revolutionizing the field, enhancing diagnosis, improving surgical precision, optimizing post-operative care, and delivering better outcomes for patients. In this article, we delve into the top 10 ways in which smart implants and AI are driving this transformation, paving the way for a new standard of personalized and data-driven patient care.

- REAL-TIME MONITORING AND FEEDBACK: Smart implants embedded with sensors and wireless connectivity enable real-time monitoring of vital parameters such as joint movement, implant performance, and tissue response. This data provides valuable insights to healthcare professionals, facilitating early detection of complications and enabling timely interventions.

- PREDICTIVE ANALYTICS FOR PROACTIVE INTERVENTION: By harnessing the power of AI and machine learning algorithms, smart implants can analyze large volumes of patient data to predict and prevent adverse events. These predictive models help identify patients at high risk of implant failure or post-operative complications, allowing for proactive interventions and personalized care plans.

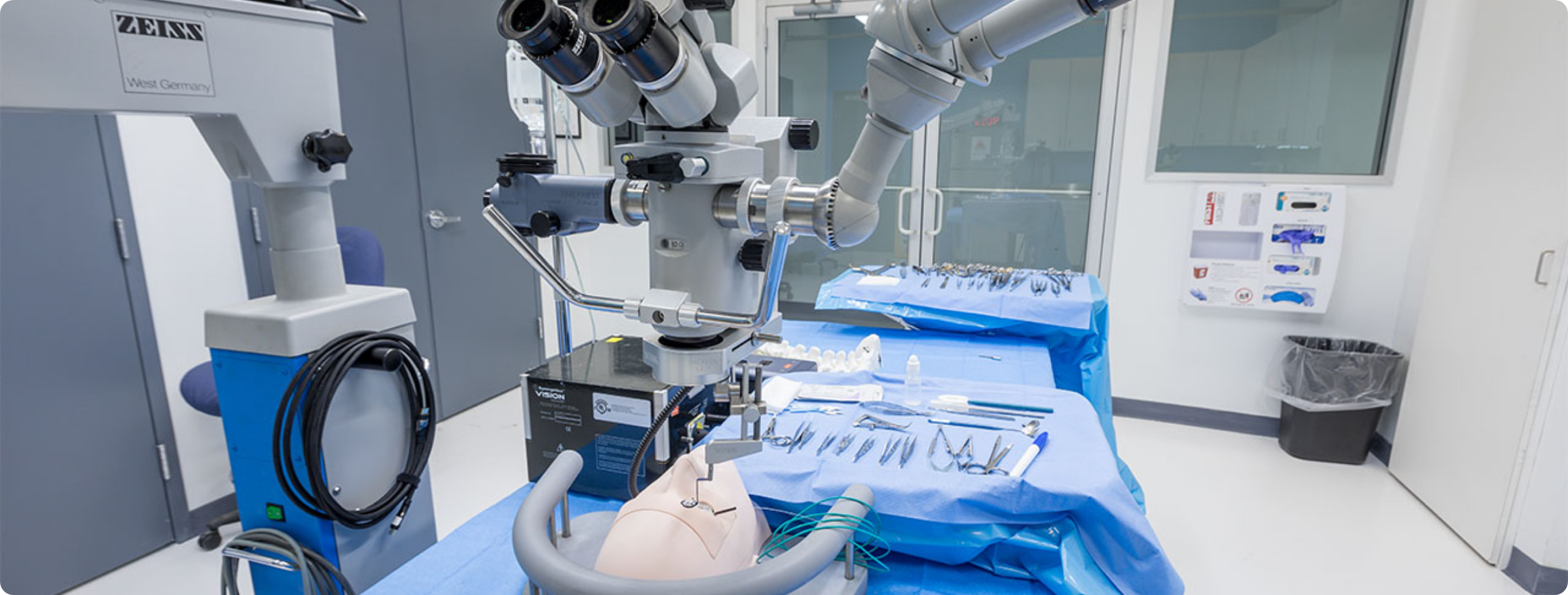

- PRECISION SURGERY AND NAVIGATION: AI-powered surgical planning and navigation systems provide surgeons with detailed anatomical information, assisting in precise implant placement and alignment. This technology improves surgical outcomes, reduces complications, and enhances patient satisfaction.

- INTELLIGENT REHABILITATION AND PHYSICAL THERAPY: Smart implants, in conjunction with AI-driven rehabilitation programs, enable personalized and adaptive physical therapy. By monitoring patient progress and adjusting therapy regimens in real-time, these systems optimize recovery and rehabilitation, leading to faster and more successful outcomes.

- ENHANCED PATIENT ENGAGEMENT AND EDUCATION: Smart implants equipped with patient-centric interfaces and mobile applications empower patients to actively participate in their own care. These technologies provide educational resources, track progress, offer reminders, and enable direct communication with healthcare providers, fostering a collaborative and engaged patient experience.

- REMOTE MONITORING AND TELEHEALTH: AI-powered remote monitoring solutions enable healthcare providers to remotely assess patient progress, detect potential complications, and provide virtual consultations. This approach improves access to care, reduces healthcare costs, and enhances patient convenience, particularly for those in remote or underserved areas.

- DATA-DRIVEN TREATMENT DECISION MAKING: AI algorithms can analyze vast amounts of patient data, clinical trials, and research studies to provide evidence-based treatment recommendations. This data-driven approach enhances treatment decision-making, optimizing outcomes and reducing variability in care.

- PERSONALIZED IMPLANT DESIGN AND MANUFACTURING: AI algorithms can analyze patient-specific data, such as anatomical scans and biomechanical parameters, to design and manufacture personalized orthopedic implants. This customization improves implant fit, functionality, and patient satisfaction.

- PREDICTIVE MAINTENANCE AND LONGEVITY ASSESSMENT: Smart implants equipped with AI algorithms can continuously monitor implant performance and assess the risk of wear, fatigue, or failure. This predictive maintenance approach allows for proactive interventions, reducing the likelihood of unplanned revisions and improving implant longevity.

- BIG DATA ANALYTICS FOR RESEARCH AND INNOVATION: The integration of smart implants and AI generates vast amounts of patient data, contributing to large-scale data repositories for research and innovation. AI algorithms can analyze this data to identify trends, patterns, and insights, leading to breakthroughs in orthopedic treatments, implant designs, and surgical techniques.

The integration of smart implants and AI is reshaping the orthopedic segment, unlocking new possibilities for personalized, data-driven, and patient-centric care. From real-time monitoring to precision surgery, predictive analytics to remote monitoring, these innovations are transforming the way orthopedic conditions are diagnosed, treated, and managed. As we continue to explore the potential of smart implants and AI in orthopedics, it is evident that this convergence will play a pivotal role in improving patient outcomes, reducing healthcare costs, and advancing the field of orthopedic medicine into a new era of innovation and excellence.

Moreover, the article also acknowledges the importance of orthopedic product development, design, and consulting in driving these advancements. Medical device engineering consultants are key players in translating concepts to commercialization, ensuring the successful development of products such as Total Hip Arthroplasty Systems, Total Knee Arthroplasty Systems, Trauma Plates and Screw Systems, Surgical Navigation Systems, Cervical Plates and Screws, Facet Screw Systems, and Interbody Fusion Devices. This collaborative effort between orthopedic design experts and engineering consultants contributes to the overall quality improvement projects within the orthopedic field. Additionally, the incorporation of concepts like augmented reality, fixation, and retractor systems further underscores the comprehensive scope of innovation within orthopedics.

Back to Insights + News